- Home

- About Company

- Our Services

- Operation and Maintenance

- Annual Maintenance Contract (AMC)

- Chemical Supply

- Motor & Pumps / Electrical Equipment Services

- Electrical Panel Board Designs

- Plant Re-Engineering / Revamping

- Spares & Accessories(New / Old)

- ZLD Projects – Erection and Commissioning

- Oil Skimmer and Dissolved Air Flotation (DAF)

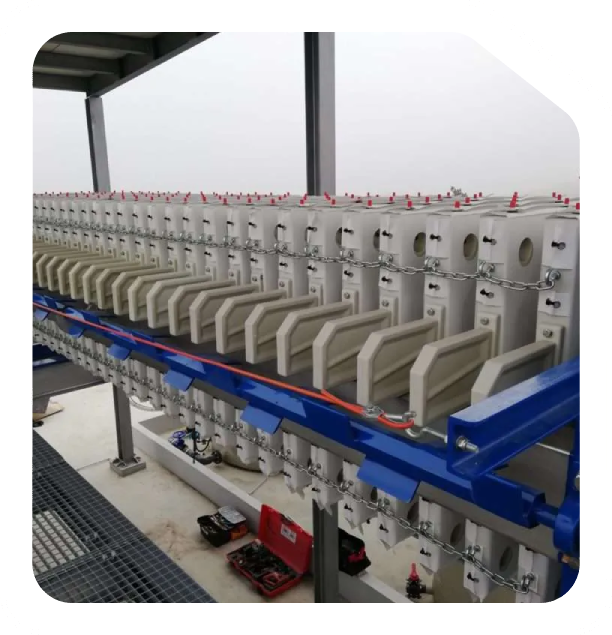

- Filter Press & Decanter Services

- Solutions

- Resources

- Contact Us

- +91-81221 29759

- newway@newwayaquatech.in